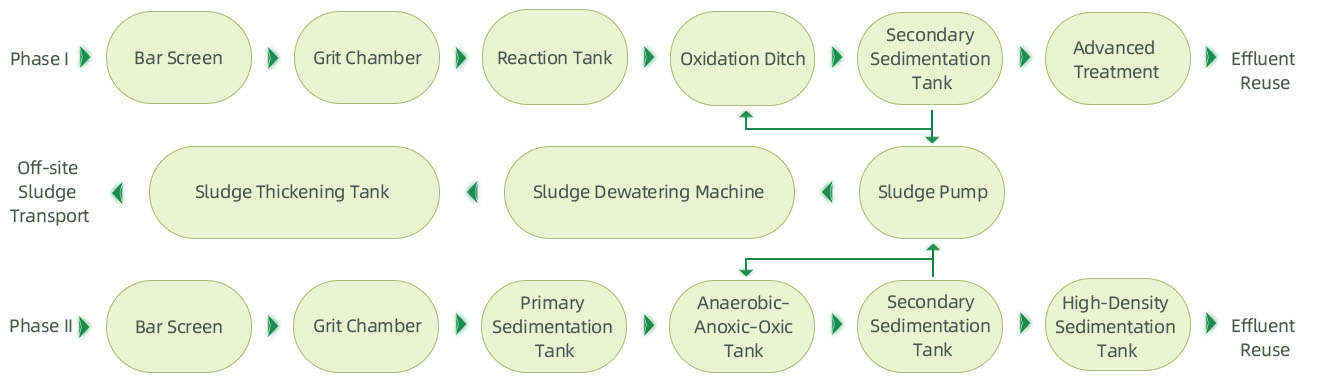

The wastewater treatment facility was constructed in two phases.

Phase I has a treatment capacity of 50,000 m³/day and adopts three parallel Orbal oxidation ditches. Ditches A and B share a sludge selector and secondary sedimentation tank, while Ditch C operates independently with its own sludge return system.

Phase II applies the AAO process for nitrogen and phosphorus removal, also treating 50,000 m³/day.

After treatment, the effluent undergoes advanced treatment before being discharged into the receiving natural water body.