1.1 Key Pollutants:

DNT, MNT, RDX, etc.

1.2 Key Characteristics:

(1) High aniline and nitro compound content

(2) High ammonia nitrogen and COD

(3) High salinity and color intensity

(4) Complex influent composition

(5) Vulnerable to shock loads

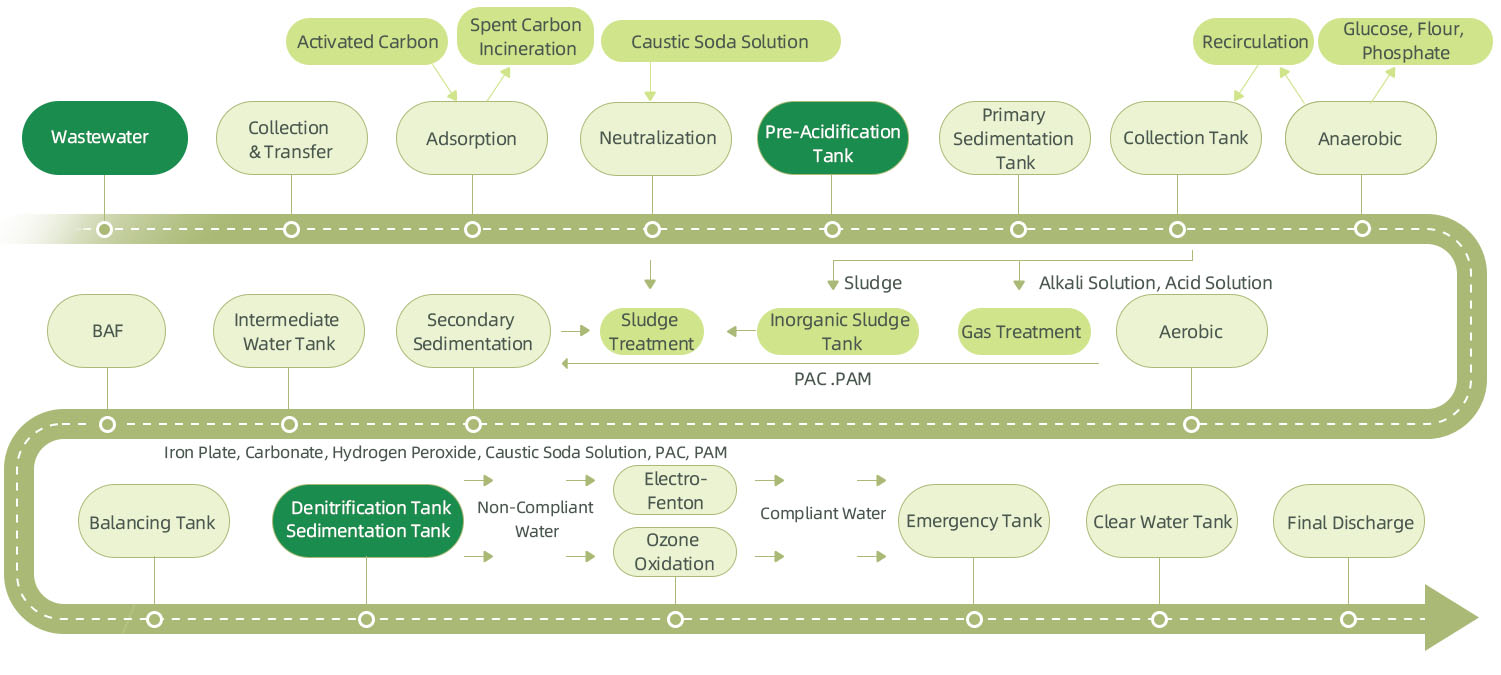

Solution:The EPC turnkey project for upgrading industrial wastewater treatment standards was highly challenging. Our solution covered site investigation, process design, equipment procurement, civil works, mechanical and electrical automation installation, and process commissioning.

Processing Scale:180m³/h

Treatment Effect:To address high ammonia nitrogen and total nitrogen concentrations, an anaerobic system was added to enhance wastewater biodegradability. The aeration system was optimized by replacing the original swirl aeration with a liftable aeration system, enabling rapid installation without interrupting water flow. The BioMore® JunoNitroRem Bioreactor was applied to strengthen nitrogen removal, ensuring the effluent meets Class A discharge standards.

Characteristics

Characteristics

DNT, MNT, RDX, etc.

(1) High aniline and nitro compound content

(2) High ammonia nitrogen and COD

(3) High salinity and color intensity

(4) Complex influent composition

(5) Vulnerable to shock loads

Plant Profile

Plant Profile

改造后新增预酸化罐、反硝化罐

Description

Description

(1) Significant Fluctuations in Influent Volume and Quality

After all production plants began operating at full capacity, the volume of industrial wastewater varied significantly, and the influent water quality deteriorated. This exceeded the actual treatment capacity of the wastewater treatment facility. Without a front-end equalization tank, fluctuations in wastewater quality and quantity could not be effectively adjusted in time.

Parameter | Average(mg/L) | Maximum(mg/L) |

COD | 3700 | 7710 |

NH3-N | 223 | 771 |

TN | 623 | 1200 |

(2) Limited Maximum Treatment Capacity

The maximum capacity of the three biological treatment units for raw wastewater was limited to 60 m³/h.

(3) Insufficient Oxygen Supply in the Aerobic Tank

The swirl aerators in the aerobic tank had low oxygen transfer efficiency. Additionally, the air supply valves for both the aerobic tank and the BAF tank were non-adjustable due to aging and corrosion, limiting proper air distribution.

(4) Lack of Total Nitrogen Treatment Measures

At the end of the process, there was no dedicated stage for total nitrogen removal, particularly for nitrate nitrogen. Although NH₃-N was effectively converted to nitrate nitrogen through the aerobic system and electro-Fenton process, which allowed the ammonia levels to meet increasingly stringent discharge standards, the total nitrogen concentrations still did not comply with the rising regulatory limits.

(5) Absence of Biochemical Pretreatment Unit

The wastewater entered the UASB system after undergoing activated carbon adsorption and pH adjustment. However, due to the complex composition of the wastewater, including large-molecule, long-chain heterocyclic nitro compounds, and amine compounds, it caused significant strain on the operation of the UASB system.

Option

Option

(1) Addition of a Pre-Acidification Tank

Hydrolytic and acidogenic bacteria were introduced to release enzymes that biologically catalyze the breakdown and solubilization of large, poorly biodegradable organic molecules in the wastewater. The resulting soluble substrates were then utilized by microorganisms for intracellular biochemical reactions, during which various organic acids were produced and discharged.

(2) Aeration System Upgrade

The original Roots blower was replaced with a centrifugal blower. Due to the aging of existing swirl-type aerators and insufficient dissolved oxygen supply, the aeration system in the aerobic tank was upgraded. A retractable aeration design was adopted to enhance operational efficiency and ease of maintenance.

(3) Enhanced Nitrogen Removal

Considering the plant layout and influent characteristics, a BioMore® JunoNitroRem Bioreactor was installed downstream of the equalization tank to achieve thorough nitrogen removal. This process offers a compact footprint, fast installation, low sensitivity to seasonal changes, high denitrification efficiency, and reduced carbon source dosing costs. Positioned before the electro-Fenton unit, it also enables residual COD to be removed efficiently without requiring additional COD-removal equipment or chemicals.

Service Content

Service Content

Process Control Optimization

Process Control Optimization

Standard Operating Procedure Development

Standard Operating Procedure Development

Performance Assurance & 24/7 Support for emergencies

Performance Assurance & 24/7 Support for emergencies

Assessment of the effectiveness and optimal dosage of physical and biological treatment chemicals

Assessment of the effectiveness and optimal dosage of physical and biological treatment chemicals

Experimental evaluation and tailored recommendations for different wastewater streams from various workshops.

Experimental evaluation and tailored recommendations for different wastewater streams from various workshops.

Technical training and updates on best practices and emerging environmental technologies.

Technical training and updates on best practices and emerging environmental technologies.  Periodic Service

Periodic Service